The supply chain is the backbone of any company that depends on physical products for revenue. From raw materials to finished products, your supply chain is responsible for ensuring that everything is in the right place at the right time. But along with the importance of the supply chain comes potential downsides. Supply chain disruptions can be significantly costly for you. In this article, we’ll explore the impact of supply chain disruption on manufacturers, the common causes, and the importance of supply chain management to mitigate these issues.

Supply Chain Disruption and its Impact

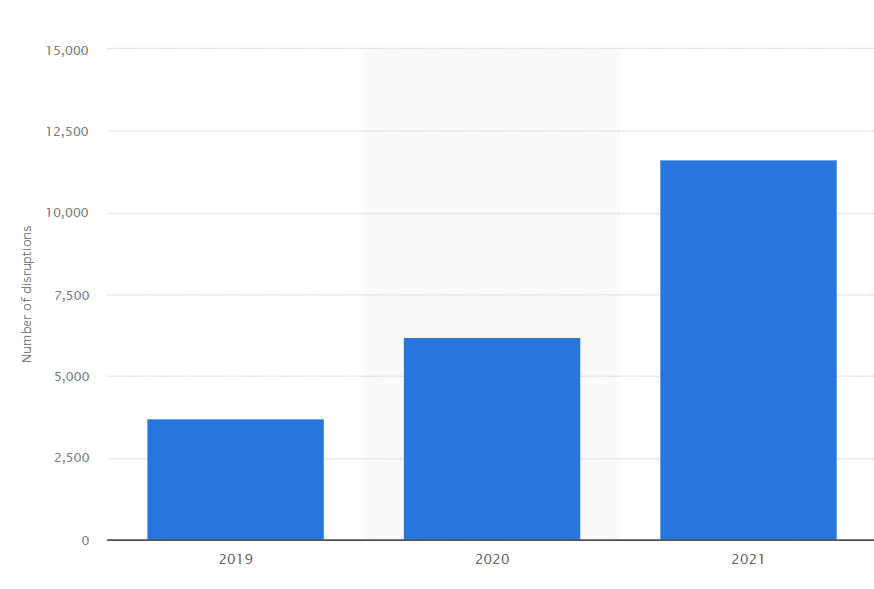

As evidenced by the chart, in recent years there has been a drastic increase in global supply chain disruptions.

The global supply chain is expected to face continuing constraints in 2023 due to ongoing conflicts such as the war in Ukraine, as reported by the Harvard Business Review. And according to DDC, concerns about supply chain sustainability and corporate practices are on the rise in 2023.

Supply chain disruption affects the flow of goods and services to manufacturing. This can be caused by a variety of factors, but when a supply chain is disrupted, it can have a significant impact on your ability to deliver products on time. Without the necessary raw materials or components, production can grind to a halt. Missed deadlines, delayed shipments, lost sales and damage to your reputation are not far behind.

Overall, the business outcomes of supply chain disruptions can be significant, especially for small and medium-sized companies who have less wiggle room to handle these situations.

Common Causes of Supply Chain Disruption

There are many potential causes of supply chain disruption. Here are the big hitters:

- Natural disasters: Hurricanes, earthquakes, and floods can disrupt transportation and cause delays in the delivery of raw materials and finished products.

- Labor disputes: Strikes and lockouts can lead to supply chain disruption.

- Supplier business issues: Issues like bankruptcy can cause significant disruption in the supply chain.

- Minor disruptions: Aspects like a transportation breakdown or a delay in customs clearance can have a cascading effect on the supply chain.

- Lack of visibility: A lack of visibility into the supply chain can lead to delays, disruptions, and inefficiencies.

- Poor communication: Poor communication between suppliers, manufacturers, and distributors can lead to miscommunications, delays, and mistakes.

- Inventory management: Poor inventory management can lead to overstocking or understocking, which can create inefficiencies and impact the supply chain due to increased needs.

- Quality control: Poor quality can lead to reduced production yield, which can cause delays and impact customer satisfaction.

- Cybersecurity threats: Cybersecurity threats can lead to data breaches or system failures, which can compromise the integrity of the supply chain.

With the variability of potential causes of supply chain disruption that can impact your business, you need to be prepared to address and mitigate these disruptions. Proper management will ensure your supply chain’s smooth functioning and minimize the impact on your business operations and customers.

Top aspects of Supply Chain Management

Effective supply chain management is the answer to helping you minimize the risk of supply chain disruption. By coordinating all activities and processes in the supply chain, you can better ensure the ability to produce and deliver high-quality products to customers.

In order to realize the benefits, you need to make sure you’re covering the integral aspects of the supply chain:

- Supplier management: This involves engaging the right suppliers up front who are able to produce effectively based on all the requirements of your product. It also involves managing and maintaining relationships with those suppliers, including negotiation of contracts, monitoring supplier performance, and ensuring compliance with regulations and standards. Effective supplier management helps to ensure the reliability and quality of supplies and services, improve communication, and reduce costs.

- Procurement: Procurement is another critical aspect of supply chain management that involves sourcing and acquiring raw materials and goods from suppliers. In addition to managing the suppliers, you need to know aspects of the suppliers like lead times, so you can order parts no later than the stated lead time to ensure timely delivery. Be aware that in the last few years lead times have unexpectedly and significantly increased causing trickle down shortages throughout the supply chain.

- Inventory Management: Effective inventory management is also essential to your supply chain management. It ensures that you maintain the right amount of inventory to meet demand while avoiding stockouts and excess inventory costs. This requires real-time visibility into inventory levels, accurate demand forecasting, and effective inventory optimization strategies.

- Logistics: Logistics is a critical aspect of supply chain management that involves the movement of products and materials from suppliers to manufacturers, distributors, and customers. You need to engage in careful planning, efficient transportation, and optimal inventory management to minimize waste and ensure timely delivery.

- Risk management: It involves identifying, assessing, and mitigating risks that can disrupt the supply chain. This includes natural disasters, labor disputes, quality issues, cybersecurity threats, and other potential disruptions. Effective risk management helps to ensure the continuity of the supply chain and minimize any potential negative impact on business operations.

By optimizing each of these areas, you can create a more resilient supply chain that can better withstand disruptions.

The Role of Supply Chain Visibility & Analytics in Avoiding Disruption

Proper supply chain management requires visibility and a deep understanding of your entire supply chain, including suppliers, transportation, inventory management, and demand planning. Unfortunately, only 6% of companies report full visibility on their supply chain.

By leveraging visibility and different types of analytics, organizations can gain a better understanding of their supply chain processes, identify potential risks and disruptions, and take proactive measures to mitigate them.

Some of the top areas to analyze include:

- Demand forecasting: This helps to forecast how much inventory will be needed to meet customer demand, reducing the risk of over or understocking.

- Inventory optimization: This allows you to determine the optimal level of inventory needed to meet demand, while minimizing carrying and holding costs.

- Supplier performance monitoring: This provides insights into how well your suppliers are performing, enabling you to make strategic decisions about supplier relationships.

- Logistics optimization: This helps to optimize transportation and logistics operations, reducing transportation costs and improving delivery times.

- Risk awareness: Being proactively aware of risk helps to identify and mitigate supply chain issues, such as supplier disruptions or natural disasters, and reduces the impact on your business and its customers.

Leveraging Supply Chain as a Competitive Advantage

Beyond the benefits for you and your customers, an effective supply chain can be a significant competitive advantage. In fact, 57% of companies believe that supply chain management gives them a competitive edge.

By optimizing the supply chain, you can ensure that you’re delivering products on time and at a lower cost than competitors.

Additionally, a resilient supply chain can help you weather disruptions and emerge stronger than competitors. By leveraging supply chain as a competitive advantage, you can position yourself for long-term success.

Case Studies of Successful Supply Chain Management

There are many examples of successful supply chain management in the manufacturing industry.

A couple larger examples are Toyota, which has developed a highly efficient and resilient supply chain that can respond quickly to disruptions, and Apple, which has created a global supply chain that allows it to deliver products on time and at a lower cost than its competitors.

From a smaller business perspective, at Zebulon Solutions, we worked with a company who got hit hard by the supply chain disruptions due to Covid.

Their contract manufacturer suddenly could no longer find the parts to produce their product, and told our client they needed to find the parts themselves. They needed to act quickly and engaged Zebulon to help.

We were able to do the sourcing research, and amass a group of new suppliers, a couple brokers, and some distributors that across them could cover the supply chain needs throughout the Covid related distruption. In essence, it was a mesh of coverage that kept our client’s products in the marketplace, and their business moving forward despite the global supply breakdown.

By studying these examples, you can learn best practices for effective supply chain management.

Mitigating the Cost of Supply Chain Disruption

The cost of supply chain disruption can be significant. However, aligning visibility, analyzation and implementation of the aspects of supply chain management we’ve discussed can mitigate these costs.

If you’re handling this internally, a couple easier ways to mitigate disruptions is to maintain a safety stock of critical and long lead components. This can help minimize the impact of supply chain disruptions by ensuring that production can continue even if there are delays in the delivery of these items. Additionally, you can work with suppliers to develop contingency plans to address potential disruptions.

Overall though, working with a company who has the expertise in fully managing an optimized supply chain, combined with the business relationships throughout the chain, can alleviate a majority of the issues, and provide you with numerous business benefits.

Effective supply chain management requires both strategic and tactical support, as well as a commitment to continuous improvement. By taking these steps, you can create a resilient and efficient supply chain that can withstand disruptions and drive growth.