Companies developing physical products know the struggle to get products to manufacturing in an efficient way, and the headache of issues that hinder progress. Many businesses rely on contract manufacturers or suppliers to provide the necessary parts and materials for their products, but effectively handling supplier management effectively can be complex.

In 2020, a small California-based business outsourced production of its desk trays to an Ohio-based manufacturing partner due to rapid growth and high demand. The initial shipment revealed quality issues, such as color variations and size inconsistencies, leading the small business to discover that the manufacturing partner failed to meet quality standards and had cut corners to save costs. The small business had to recall the product, refund customers, find a new manufacturing partner, and invest time and resources in rebuilding brand reputation and customer trust.

In this article, we’ll provide insights and recommendations for optimizing your supplier management processes, and building strong relationships with your suppliers to help ensure your product development efforts are successful while mitigating potential risks.

Strategic Sourcing

In order to effectively source the necessary parts for product development and manufacturing, companies must establish a strategic sourcing plan that takes into account several important factors. These include pricing, negotiation, quality control, on-time delivery, and overall performance of potential suppliers.

The plan must also involve a thorough evaluation of potential suppliers to ensure that they can meet the company’s needs. Effective communication channels must be established to ensure that both parties are on the same page throughout the process.

By considering these factors and developing a solid sourcing plan, companies can streamline their procurement process and ensure that they get the necessary parts for their products in a timely and cost-effective manner.

Pricing

Price is a significant factor in any sourcing decision, and it’s essential to ensure that you’re getting the best possible value for your money.

When comparing prices from suppliers, it’s important to look beyond just the upfront costs and consider factors like the total cost of ownership over the product’s lifecycle. When you get quotes it is important to be sure that all your prospective suppliers are quoting the exact same thing – volumes, technical details, anticipated labor (as appropriate), and bill of materials. The expectation should be for a transparent quote that lists out all of what can be hidden costs on separate line items including Value-Added Manufacturing (VAM) and profit.

For a company that is struggling to get a product to manufacturing efficiently, negotiating with suppliers who have a track record of meeting deadlines and providing reliable products may be more valuable than simply going for the lowest price option.

Negotiation

Negotiation can help to ensure that both parties are getting a fair deal, which can ultimately lead to a stronger, more collaborative relationship. Effective negotiation involves identifying the interests of both parties and finding common ground to reach an agreement that satisfies both sides.

Negotiation may cover a range of topics, including pricing, delivery times, quality standards, and payment terms. Skilled negotiators understand the importance of maintaining good relationships with their suppliers while still achieving their goals.

One key aspect of negotiation is knowing your leverage. Young companies with little to no track record and questionable finances have much less leverage in negotiation than a large established multinational corporation. The revenue a company brings to a potential supplier plays a key role in determining leverage in the negotiation. Understanding your leverage, or lack thereof, can help businesses set realistic expectations for negotiation outcomes and prepare for potential pushback from suppliers. This knowledge can also help businesses make strategic decisions about which suppliers to partner with, based on their ability to negotiate favorable terms.

The negotiation process can help to establish trust and build rapport between the buyer and the supplier, which can lead to better outcomes for both parties in the long run. By effectively negotiating with suppliers, businesses can ensure that they are getting the best possible value for their money while maintaining strong relationships with their suppliers.

Quality Control

Ensuring the quality of parts received from suppliers is crucial for the final product. This requires establishing quality control procedures, such as inspection criteria and regular audits, and working with suppliers to ensure they have the necessary certifications and quality management systems.

Here are some ways to work with suppliers to establish quality control processes and ensure that they have the necessary certifications and quality management systems in place:

- Set clear quality standards: Establish clear quality standards and specifications for the product, including acceptable tolerances and defects. This includes cosmetic standards, as a lot of times what may be seen as manufacturer failures can actually be the customer’s fault for not holistically communicating requirements.

- Conduct thorough research: Thoroughly research supplier track record, quality control, certifications, and past performance before selection. Understand that even with the best of suppliers, issues will come up, so it’s important to have contingency plans (see the Procurement Risk section below).

- Regularly monitor and inspect: Insist on regular quality checks and inspections throughout manufacturing, including spot checks and audits. As the customer it is important to trust but verify the manufacturing performance and be actively involved, while not micromanaging the supplier.

- Provide feedback: Provide regular feedback to the supplier regarding their performance and quality control processes so the supplier can make necessary adjustments. Most suppliers will welcome constructive feedback to improve their processes and yields, so don’t be afraid to provide it.

- Collaborate on continuous improvement: Work with the supplier to identify areas for continuous improvement in the quality control process, including sharing best practices and collaborating on ways to improve product quality and consistency.

On-time Delivery

On-time delivery is another critical factor to consider when sourcing products. You need to ensure that your suppliers can deliver the products you need on time and do so consistently. This means establishing clear expectations around delivery schedules and working with suppliers to put in place contingency plans in case of any disruptions or delays.

Overall Performance

When evaluating potential suppliers, it’s important to consider their overall performance beyond just their pricing, quality, and delivery. This includes factors like their experience, reputation in the industry, and their track record of consistently delivering high-quality products.

Supplier Relationship Management

Building and maintaining a positive relationship with suppliers is essential to ensure the timely delivery and high quality of parts. This may include developing performance metrics, providing feedback on performance, and recognizing and rewarding excellent service.

Communication

Clear communication is vital to ensure that suppliers understand the requirements and expectations for the parts they supply. Companies should establish communication channels, and regular check-ins should be held to provide feedback and promptly address issues.

Providing and seeking feedback can improve the overall supplier management process, and regular check-ins and progress updates during the negotiation process can help align both parties and address any issues promptly.

Supplier Management Tools

Supplier management software centralizes supplier information, aids communication, and tracks supplier performance. Combining communication channels, collaboration tools, supplier portals, and ERPs enables analyzing supplier performance and improving collaboration.

- Communication channels: Email, phone calls, video conferencing, and in-person meetings are all useful methods for transmitting important documents, updates, and inquiries. These channels help to ensure that both parties are on the same page about collaboration and can maintain a strong working relationship.

- Collaboration tools: Platforms like Slack, Asana, and Trello can improve communication, task management, and workflow efficiency between you and your supplier.

- Supplier portals: Web-based systems that allow for easy access to information and collaboration between you and your supplier.

- ERP: Implementing an Enterprise Resource Planning (ERP) system can be an effective way to manage suppliers and streamline procurement processes. An ERP system can help businesses keep track of supplier performance, identify which suppliers are qualified to make certain parts, and monitor inventory levels in real-time. With an ERP system, businesses can easily track supplier lead times, delivery schedules, and quality metrics, which can help improve supplier relationships and reduce the risk of supply chain disruptions.

ERP systems like Agile, Oracle, and Arena, as well as the Parts Dashboard platform, can provide a centralized view of supplier information, including who is the primary supplier and who are the alternate suppliers. This information can help businesses make informed decisions about which suppliers to work with, and can also help identify potential supply chain risks before they become major issues.

The implementation of supplier management software can significantly improve supplier management processes. By centralizing supplier information, aiding communication, and tracking supplier performance, businesses can analyze supplier performance and improve collaboration, ultimately leading to better outcomes for both parties involved.

Procurement Risk Management

Supply chain disruptions can have a significant impact on product development timelines and costs. Therefore, it is essential to establish risk management procedures to identify potential risks and develop strategies to mitigate them. This may include conducting regular risk assessments, setting up contingency plans, and establishing those clear communication channels with suppliers.

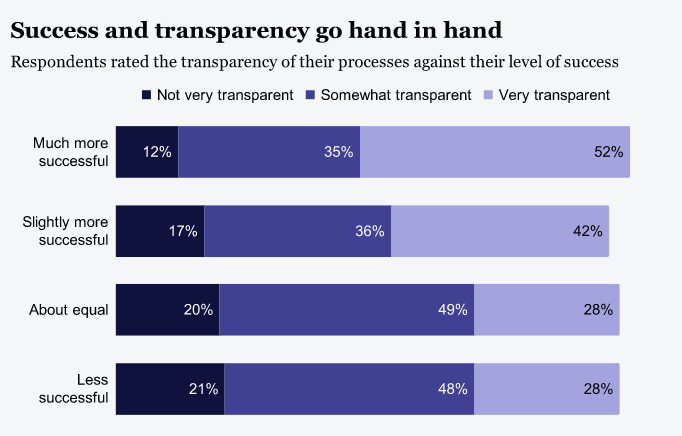

60% of procurement leaders say that a lack of transparency is a risk to their companies. The chart below shows the direct correlation between procurement success and transparency to mitigate risks.

Key Contract Clauses for suppliers

Contracts between a company and its suppliers are critical components of the overall strategy for managing intellectual property risks related to supplier management. In addition to outlining the terms and conditions of the relationship, these contracts should include key clauses related to intellectual property ownership, use, and protection.

For example, the contract can stipulate that the supplier will not use any proprietary information or trade secrets belonging to the company and that any intellectual property created during the manufacturing process will be owned by the company. Non-disclosure agreements (NDAs) are also common clauses in supplier contracts, as they protect sensitive information and trade secrets. NDAs ensure that suppliers cannot disclose confidential information about the company to third parties without the company’s express permission.

Another important clause in supplier contracts is the indemnification clause, which protects the company from any losses, damages, or liabilities arising from the supplier’s work. The indemnification clause can specify that the supplier will be responsible for any claims or damages resulting from defects in their products, services, or materials.

Finally, termination clauses are essential components of supplier contracts, as they outline the conditions under which either party may end the relationship. Termination clauses can specify a notice period for ending the contract, the reasons for termination, and the obligations of both parties after termination. By including these key clauses in supplier contracts, companies can ensure that they are protected from potential legal and financial risks while maintaining strong relationships with their suppliers.

Due Diligence for Supplier Selection

Due diligence is the process of conducting a thorough investigation into a potential supplier to ensure they have the necessary skills, resources, and reputation to meet the company’s needs. This of course goes hand-in-hand with aspects of the strategic sourcing we already covered, but includes conducting background checks, reviewing financial statements or Dunn & Bradstreet ratings, and assessing the supplier’s overall track record.

In the context of intellectual property risks, due diligence can include reviewing the supplier’s policies and procedures for protecting intellectual property, as well as any past legal disputes related to intellectual property infringement.

Contingency Planning

Unexpected events can occur at any stage of the procurement process and can pose a significant risk to a company’s supply chain. These events can range from natural disasters and economic disruptions to supplier bankruptcy or labor disputes. By having contingency plans in place, companies can better prepare for these unexpected events and minimize their impact on the procurement process.

Additionally, it’s essential for companies to regularly review and update their contingency plans to ensure that they remain relevant and effective in mitigating risks. In addition, companies should expect regular communication from the supplier to ensure that they are aware of any potential risks or changes to the supply chain that may impact their operations.

Effective supplier management is critical for the success of small businesses to handle relationships with suppliers or suppliers and get the parts needed. Strategically sourcing the right suppliers, managing the relationship well, and mitigating risks related to your suppliers are essential when selecting and working with suppliers.

Managing supplier relationships, supply chain, and product manufacturing can be complex and time-consuming. Supplier management services like those included when working with Zebulon Solutions can help streamline these processes and ensure that your products are manufactured to the highest quality standards, and in a timely manner, to align with your needs.