Hardware marathon: Installment 9

This post is the final installment in the series, “The Hardware Marathon”. In this series, I discuss the process involved in developing a hardware product from concept to production.

Our runner has almost finished the race as observed by the growing crowds that line the street, cheering the runners on. The race has been arduous, repetitive and there have been times our runner felt like the finish line would never be in sight. But now, just passing the 25th marker, our runner, with a tired body, has renewed strength knowing the race is nearly done.

Considering the marathon you’ve been in developing your product, you are nearly ready to focus your attention on sales and the daily operations of your business without also focusing on the myriad of details associated with hardware development. While you can’t really hand everything to your contract manufacturer (CM) and walk away, your involvement will decrease because you are paying for a CM to manage the day-to-day activities. The CM will ensure they have the necessary parts, quality of the product produced meets the requirements, and your orders are shipped out as agreed.

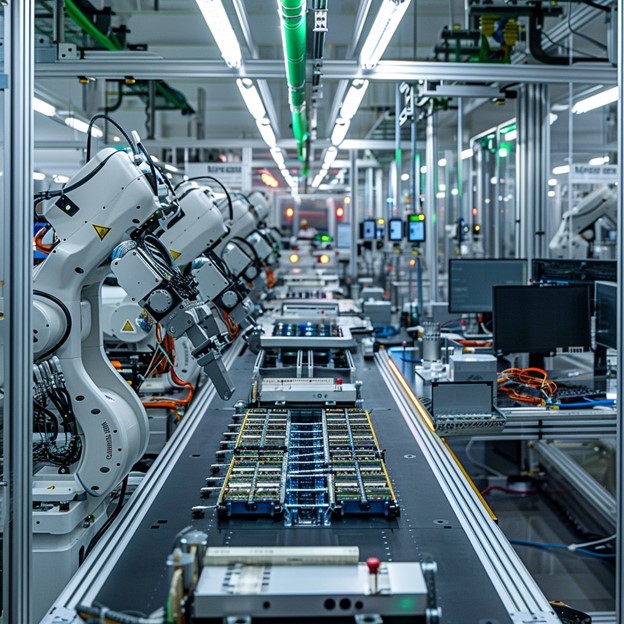

Keeping the production machine going

You’ve been working with your CM for a few months now and have gotten through the bumpy introduction to production in Pilot. You have a better understanding of how your CM operates and communicates with you. Regardless of who your CM is, there are some industry-standard tools used for efficient planning and communication:

Purchase Orders (PO) – you’ve already placed at least one PO for the initial production, and you will continue to place POs for as long as you do business with your CM. It is the primary tool to communicate what you want them to build, how many you want built, the agreed upon cost, and when and where you want them delivered. It should also include the delivery terms for when you will take ownership of the parts (see Incoterms®).

It is also important to consider how you are going to manage your POs. You could issues a blanket PO that would cover the entire quantity you want to purchase for the next 6 – 18 months and identify how many you want shipped each month or quarter. This is a great way to provide visibility to your CM to ensure they have the necessary resources and to include you in their planning as well as avoid changes in terms and delays due to lead time. Some adjustments in quantity and delivery schedule can be made, but reducing the total quantity could result in increased product cost.

Another way to mange your POs is to place a new order every time you want them to build product for you. It gives you more flexibility if you don’t know your market demand and it doesn’t lock you into a quantity or delivery schedule. The downsides are you will need to ensure you are including production and material lead time when placing orders and your CM may requote the cost of your product with each PO you place.

Forecasts – regardless of the approach you take for placing POs, your CM will benefit from having an annual forecast. This is an informal document showing what you plan to order each month or quarter. The CM will use this in their resource planning. They can tentatively put you into their schedule, which can help to mitigate lead time and maintain the quoted cost. They won’t, however, purchase material for the forecast so you could be subject to material lead times beyond their control. This visibility allows them to be more adaptive to better meet your delivery needs.

Production Schedule – CMs will develop a schedule with all the builds for their customers. They use POs and forecasts to develop the schedule and plan the resources they need. It is unrealistic to expect the CM to schedule your work tomorrow, as they need to manage their other customers. You may need to wait a few weeks for your turn. Of course, it is possible to increase your priority by paying an expedite fee for overtime and weekends for the production staff. It is worth exploring if you have a critical delivery.

Inventory Management – A plan needs to be developed to get the finished product from your CM into the hands of your customers. You may elect to do this in your own facilities and hire staff to receive bulk-packaged product and then repackage it to fulfill your customer orders. Your CM may offer these services where they would hold your inventory and ship it to the locations you specify. This approach works best with corporate or industrial products where your customers order bulk quantities.

You could engage with a third-party logistics company, a “3PL”. They would act as your shipping and receiving department. You would need to work out how they engage with your CM inbound orders and how they would know what to ship to your customers. Typically, these companies charge for warehouse space and an hourly rate for receiving, inspecting, and shipping product. Some offer different services such as rework, testing, or kitting should your product need to be modified or verified after they receive it. Like a CM, they would operate under a contract for the agreed services.

Each of these tools need to be managed on an on-going basis to ensure all the parties have the information they need to operate efficiently. Managing production is not like ordering products through an online store as it requires regular communication.

the reality of manufacturing variation

Throughout the development process, we have been discussing the importance of testing your product. In the Pilot blog, we touched on the necessity of setting a production test. One of the reasons for testing is to capture manufacturing variation. When a product is designed, the assumption is that 100% of the parts made will be good. Unfortunately, this is not a reality because manufacturing variation will inevitably create some defective parts. Product defects along with other suboptimal assembly or functional changes should be captured for the next version of the product – which will start much of this development process over again!

“There are a lot of things that come out of production that help [you] figure out if [you] have a good product or not, or if [you] need to tweak it”, said Zebulon Solutions Supply Chain Manager, Teresa Neeley.

While your CM has the knowledge to make good parts, the burden is still on you to define the narrow line between good and bad – especially if there are cosmetic requirements with your product. When a product is made that doesn’t meet the definition of “good”, the CM will set it aside for you to judge if it is good or bad. Your decision will determine if the allowance of acceptable variation is increased or if it is narrowed. If you haven’t already established a golden sample, now is a good time to do so and it can be extremely helpful when evaluating cosmetic variations.

Key Insight: The tighter any specification is, the more expensive your product will be due to declining yields. It is worth compromising as much as you believe your customers will compromise with you.

impact of production yield

The obvious goal is to have a very tiny percentage of defects so that your product costs aren’t impacted and ensure adequate product is available to support sales. The impact of tightened specifications could decrease yields, the amount of good product you get off the production line. When your CM quoted your product, they assumed a certain yield. If your product performs below this, they would likely increase your unit price to accommodate their loss in time, materials, and labor. If your product has a higher yield than they quoted, it is an opportunity to negotiate a price reduction.

Beyond the impact on price, when production yields are lower than expected, there can also be an impact on customer deliveries. The time to make a good part is the same as making a bad part, which increases the time needed to make your delivery quantity. Depending on the manufacturing capacity of your CM and how low the yields are, it is possible that your orders will be delayed in shipping.

long term cm engagement

Up to this point, you’ve been heavily involved in every detail of your product, but in production your manufacturing partners assume day-to-day ownership. They will address delivery and quality issues and only escalate issues to you that impact their ability to deliver on-time, increase your product costs, or fail to meet your quality standards. Even though they will manage most of the details, it is paramount to have on-going communication and management oversight; it is your product after all.

At Zebulon Solutions, we recommend at least quarterly reviews with the CM. It is important to look at how production is going and verify the product is meeting the target yields. It is a time to review the challenges they’ve had as well as how effectively they’ve solved them. While you were hopefully made aware of any serious issues, there are other minor concerns that are worth discussing and considering how future redesigns could address these problems to improve the cost-structure of your product.

During the quarterly reviews, it is good to provide feedback to the supplier based on your own key performance indicators (KPIs) such as on-time delivery, customer returns for warranty issues, and pricing fluctuations. It is an opportunity for price negotiations and as your CM becomes more familiar with your product, they can provide feedback on areas that impact pricing. This open dialog between you and your manufacturer allows them to continue to meet or exceed expectations and discuss areas for improvement in the product.

the finish line

With production running smoothly and inventory being predictably produced, you have reached the finish line in this product development marathon. You’ve learned many things along the way that you will take with you the next time you design a product and repeat the hardware marathon. For now, celebrate your accomplishments and recognize the members of your team that helped get you here.

Just as our runner crosses the finish line, people are cheering on top of music blasted from loudspeakers. Some runners crawl across the finish – just making it with the last bit of energy in the tank, but they don’t give up. A race organizer puts a participation medal around their neck and they walk forward into the crowd to find their supporters. Maybe our runner will tackle another marathon. Maybe this is their only race. Regardless, they should have a sense of accomplishment and so should you.