About the Client

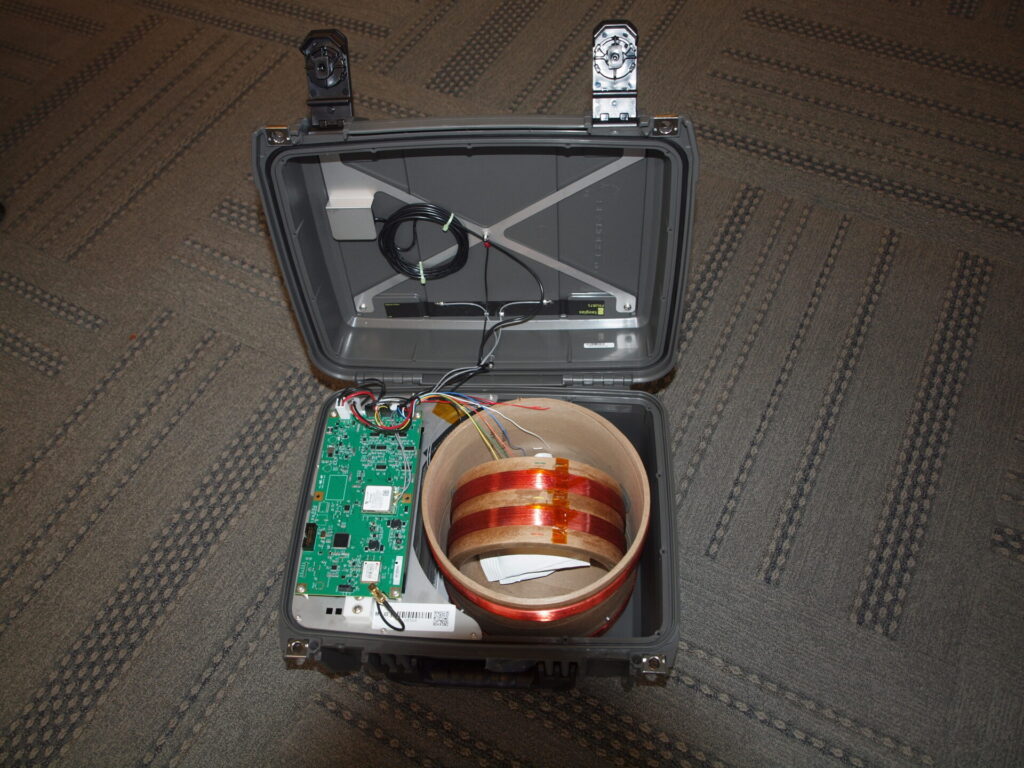

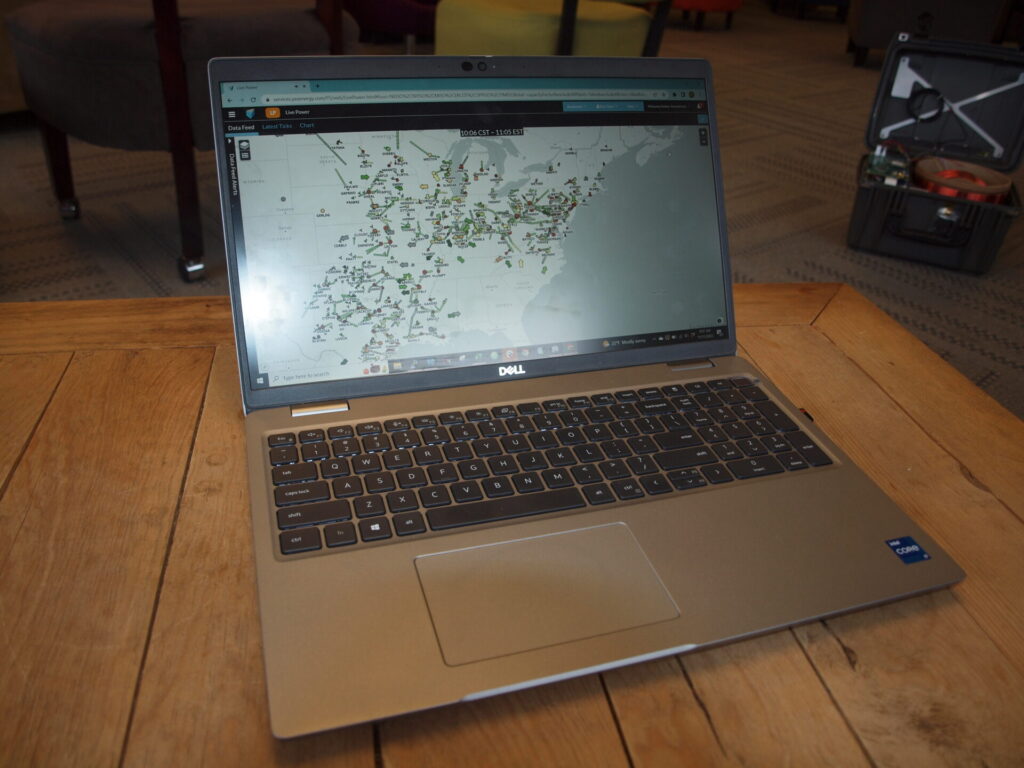

Live Power Intelligence utilizes a proprietary sensor network to collect data on energy production for their commodity trading customers. Their Measurement Sensors are strategically placed near power plants and transmission lines to remotely detect changes in the power grid and upload the information to the cloud. They process the data using proprietary analytics and send reports to customers in real-time. The sensors are solar-powered and ruggedized against extreme environmental conditions for continual outdoor operation.

Project Background

In mid-2020, the leadership team at Live Power Intelligence was under a lot of pressure. Their analytics team needed to spend more time focused on monitoring the data instead of troubleshooting the sensor outages. When the sensors were up, they were still the fastest reporting in the industry, but the field team couldn’t keep up with replacing the failures; customers’ expectations were not being met. In the early days of the business, the design of the product was adequate to prove out the concept and even collect sellable data. The failure rate in the field was manageable when only a few systems were deployed, but when over 1,200 systems were in the field, the failure rate was unsustainable.

Live Power Intelligence is a data analytics company; they are not experts in hardware design. Their internal resource who designed the complicated physics of the sensor was a creative genius, but didn’t have the expertise to design the product for ease of manufacturing nor long-term field reliability. They needed a partner who could understand what was important with their proprietary sensor and redesign it to increase field reliability without degrading performance. Live Power Intelligence had previously worked with Zebulon Solutions to develop and document the existing product design, so they reached out for help to address the field reliability issues. The team at Zebulon Solutions began by reviewing the design and identifying reliability concerns, manufacturing inconsistencies, and unnecessary costs.

Project Goals

Zebulon Solutions’ goals for the redesign of the Measurement System included:

- Reduce cost of ownership

- Improve field reliability and product life

- Remove safety hazard opening unit for repairs

- Improve system uptime, especially during winter months

- Onshore the supply chain from Norway

A Rigorous Process

Zebulon Solutions redesigned the product through several iterations, testing each round of prototypes to ensure all the components worked well together and no new product weaknesses were unintentionally created.

The redesign included a simplified PCBA with improved power management mounted in an off- the-shelf enclosure rated for the environmental extremes. During the rigorous design validation process that followed, Zebulon Solutions brutally tested the sensor against the anticipated environmental conditions in the laboratory and the field.

“Zebulon Solutions provided a lot of structure, which was nice because they have done this with other products. We had some challenges when we were testing it because the data wasn’t matching up. It was a great opportunity for the team to come together. It allowed us to deepen our connection as a team and solve problems”

Amber Armentrout

Vice President of Data Operations

Yes Energy

Navigating the Supply Chain

Since the inception of the company, the Measurement Sensors were hand-built in Norway, but several years ago the headquarters had been relocated to Colorado in the United States. Live Power Intelligence wanted to establish manufacturing Stateside to reduce shipping costs for the US market. Since this redesign occurred during the global supply chain crisis, careful planning was needed ensure continuity of supply while establishing a domestic supply chain.

Zebulon Solutions tapped its extensive network of domestic manufacturers to identify the best match for the product and business. Simultaneously, the supply chain managers proactively managed the lead time of all the components on the bill of materials to ensure every part was available to avoid unnecessary delays in the initial production of the redesigned sensor.

The Results

The redesigned Measurement Sensors have roughly 30% fewer parts, cost 40% less and have reduced errors in data transmission errors by 80%. They are safer to install, easier to repair, much more energy efficient, function in much wider temperature extremes, and last longer in the field.

“The quality of our data is invaluable to our customers and Zebulon Solutions has improved that quality of data though improving our hardware and firmware. Zebulon Solutions produced better Measurement Sensors, which has produced a better reading through the data, which creates better quality data for our customers—and they use that data to interpret everyday changing conditions.”

TJ

Vice President of

Fleet Operations at Yes Energy

The success of the project positioned Live Power Intelligence to be acquired by the power market leader, Yes Energy, in 2022. With the acquisition came an expansion of services. Yes Energy has already launched hundreds of Live Power Intelligence’s redesigned Measurement Sensors in New York and New England with the expectation that they will provide reliable data transmissions.

About Zebulon Solutions

Zebulon Solutions is a leading product design and supply chain services company that gets products out of R&D and into stable manufacturing. Our services include product design and development, supply chain services, and operational consulting. We make products ready for manufacturing by using an engineering approach rooted in experience. The results are high-quality products that can be manufactured on time and on budget.