Startups often face a significant hurdle when it comes to securing investors. There’s a common misunderstanding about how refined the prototype needs to be to attract investors and drive manufacturing forward.

This misconception creates a disconnect between startups and investors, making it harder for entrepreneurs to gain the necessary financial support. Without a clear understanding of what a finished prototype looks like, companies may struggle to move beyond developing a concept, much less a product, that is ready for the marketplace. Startups may find themselves trapped in a cycle of unmet expectations, unable to progress towards market launch.

In the following sections, we’ll delve into the challenges entrepreneurs face in securing funding, debunk the misconceptions surrounding prototyping, and provide actionable advice to help you navigate this crucial phase of your business. Our goal is to help entrepreneurs clarify the level of prototyping needed, ensuring they can attract investors and propel their manufacturing efforts forward.

Grab a cup of coffee, sit back, and let’s dive into the world of prototyping to unlock your startup’s potential!

Why Investors Care About Your Prototype

Investors are inherently risk-averse and seek assurance that their capital will be invested wisely. A prototype serves as tangible evidence of the concept, demonstrating the feasibility and potential of a product or idea. By presenting a well-developed prototype, you can provide investors with a clear vision of the final product, instilling confidence in its viability and market potential.

Proof of Quality and Credibility

A successful prototype demonstrates that you have conducted thorough research on the problem the product solves, refined the product through iterations, understand the market demand, and possess the technical expertise required to bring the product to life. This effort showcases your commitment, attention to detail, and ability to execute, which significantly reduces perceived risk for investors. It also provides tangible evidence of a well-thought-out plan, enhancing the credibility of the inventor and increasing the likelihood of securing funding.

Feedback Gathering

Prototyping also serves as a valuable tool for gathering feedback and validating assumptions. Investors appreciate entrepreneurs who have taken the time to refine their ideas through multiple iterations. A carefully crafted prototype allows investors to engage with the product, providing them with a firsthand experience of its functionality and value proposition. This experiential interaction helps investors gauge the market fit, identify potential obstacles, and visualize the path to commercial success.

One common reason why investors hesitate to provide funding to inventors is the presentation of their ideas. On numerous occasions, at Zebulon Solutions we have witnessed inventors attempting to raise investment capital by showcasing projects that resemble a science project one might expect from a high school senior, or sometimes even worse.

When the idea lacks refinement or a sufficient number of iterations, it significantly dampens investor interest. Such presentations fail to instill confidence in the inventors’ ability to execute their plans or comprehend the intricate details involved in transforming a concept into a market-ready product. Investors seek assurance that inventors possess the necessary expertise and understanding required to navigate the complexities of product development.

Attract Investors

In summary, a well-executed prototype not only instills confidence in the minds of investors but also provides them with a tangible representation of your vision. By investing time and resources into prototyping, you can significantly enhance your prospects of securing funding and attracting investors who are willing to support your journey towards market success.

The Need for a Goal-Oriented Approach to Prototyping

When it comes to prototyping, having a clear goal in mind is essential. Take a step back to define your objectives. What problem are you trying to solve? What features or functionalities are crucial to your product’s success? This will ensure you stay on track through all the iterations of your prototype (there will probably be a lot of iterations). Also, don’t forget to understand and align your goals with those of investors, increasing the chances of securing their support.

If your product is complex, it’s wise to break your prototyping process down into manageable pieces each with its own requirements that align with the overall requirements of the product. If you need to do this, make sure to recombine these features into one cohesive product prior to showcasing it to investors. You should also retest the integrated product to make sure there aren’t problems created by the entire system, even when the individual components function well alone.

Case Study: Pebble

To showcase the importance of prototyping for investment, you may remember Pebble. They gained recognition for smartwatches, offering innovative features and customizable designs.

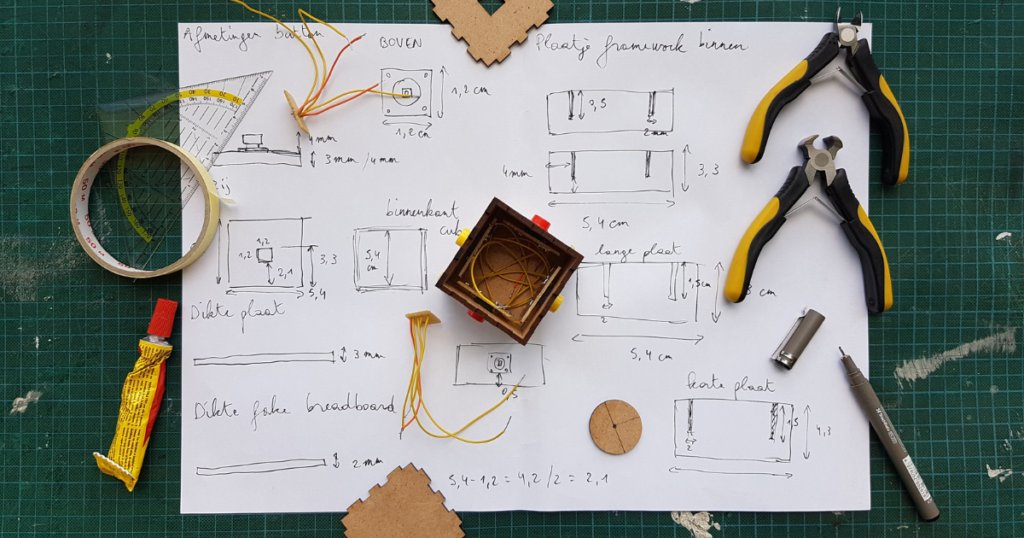

During their early stages, Pebble used prototyping extensively to refine their smartwatch concept. They created multiple iterations of prototypes using materials like foam, plastic, and 3D printing. These prototypes helped them visualize the form factor, test the user interface, and assess the overall aesthetics of the device.

Pebble was able to quickly iterate on their designs, making improvements based on user feedback and usability testing. The ability to create functional prototypes allowed them to assess the performance of the device, test different software functionalities, and ensure seamless integration of hardware and software components.

Prototyping also played a crucial role in Pebble’s funding. They used the prototypes to create engaging visuals, demonstrating the product’s features and design to potential backers. This enabled them to generate excitement and secure funding for mass production.

Through their effective use of prototyping, Pebble was able to refine their designs, identify and address any issues early on, and deliver a product to the market. Their success in leveraging prototyping as a crucial part of their product development process contributed to their emergence as a prominent player in the smartwatch industry.

Prototyping for Manufacturing: Setting Up for Success

When thinking about how to transition from prototyping to production, it’s essential to adopt a proactive mindset that focuses on manufacturing considerations. Understanding and addressing the manufacturing constraints when prototyping can significantly shorten the development timeline and reduce redundant costs when nearing production.

To set up prototypes that accurately reflect future manufacturing processes, there are several strategies to follow.

1. Break down the product components to evaluate permitted variability

Inventors often assume that every part produced will be identical, neglecting to consider the inherent variability in manufacturing processes. However, it is crucial to acknowledge that variability exists. The level of permitted variability directly impacts the cost of parts.

In particular, it is essential to focus on controlling variation in critical areas, such as interfacing surfaces. During prototyping, it’s important to consider the allowed minimum and maximum material conditions (MMC) and evaluate how the product is assembled at these specific points.

By taking these factors into account, inventors can better anticipate and address potential challenges related to material variability and assembly during production.

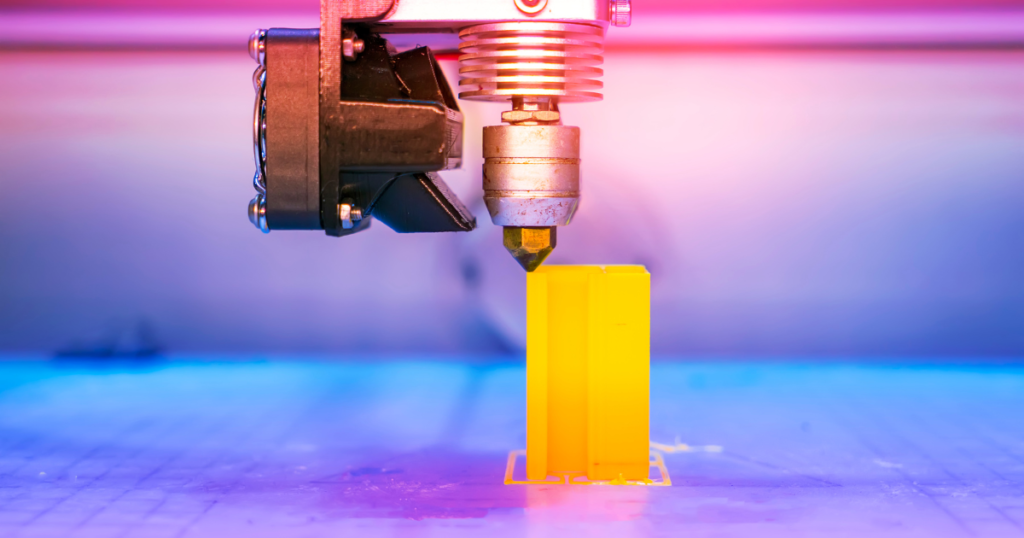

2. Consider the Fabrication Process

Aligning prototypes with manufacturing processes is crucial for a smooth and cost-effective transition from the design phase to mass production. While 3D printing has enabled the creation of complex and intricate prototypes, it is essential to consider the fabrication processes that will be used in actual manufacturing.

By replicating those constraints during prototyping, potential issues and limitations can be identified early on. This approach helps prevent significant redesigns, saves time and resources, and allows for the identification of assembly challenges ensuring a streamlined production process. Considering manufacturing processes in prototyping ensures that the final product is not only functional but also manufacturable at scale.

3. Another vital aspect to consider is scalability

A prototype may work well on a small scale, but will it translate effectively to larger quantities? It’s crucial to evaluate the design’s scalability, ensuring that it can be efficiently produced in larger volumes without sacrificing quality or incurring redesign costs. This evaluation may involve assessing production techniques, materials availability, and production equipment requirements.

When constructing small quantities of prototypes, it is crucial to respond to every defect encountered rather than dismissing it as an isolated incident. Each defect exposes a potential design issue that, if left unaddressed, could escalate rapidly and result in costly problems during production.

By thoroughly analyzing and addressing defects during prototyping, businesses can mitigate the risk of these issues multiplying and incurring significant expenses during the manufacturing process.

4. Cost-effectiveness is also a key consideration

Analyzing the production costs associated with your prototype and identifying areas where efficiencies can be achieved and tolerances are allowed. By considering factors such as material selection, manufacturing processes, and component availability, you can streamline the production workflow and minimize costs without compromising the product’s integrity.

5. Assembly requirements play a significant role in successful manufacturing

Assessing the ease and efficiency of prototype assembly is crucial to identify potential bottlenecks or challenges that may occur during mass production. It is essential to evaluate the tools required for assembly, determining if standard tools or specialized equipment are needed.

Often, inventors overlook the importance of designing products that can be assembled without individual adjustments or tweaks based on feel, as this approach leads to a costly and unreliable manufacturing process.

Instead, working towards incorporating basic tools, and utilizing precut tape or gaskets for adhesive or seal requirements can streamline assembly. While dispensing glue is a common solution, it poses risks of uncontrolled amounts, either excessive or insufficient. Considering these factors and aiming for standardized and controlled assembly processes enhances manufacturability and reduces the likelihood of defective units.

The Crucial Role of Prototype Testing in Long-Term Success

When it comes to the long-term success of your product, testing the prototype is essential. It’s not enough to simply have a functional prototype; it must also meet the needs and expectations of your target users. This is where the concept of “fail early, fail often” comes into play.

MVP Methodology

The idea behind the minimum viable product (MVP) methodology is to embrace a mindset that encourages frequent testing and learning from failures throughout the development process. By actively seeking feedback and identifying areas for improvement, you can address issues early on, saving time and resources in the long run.

User-based testing, functional testing, reliability testing, environmental testing, and other physical tests are crucial to ensure the success of a product and unlock investor confidence.

Here’s an overview:

User-Based Test

User-based testing goes beyond engaging users with the product; it involves understanding how the product will be used and replicating real-world scenarios to test its performance in those conditions.

By considering the user experience throughout the testing process, designers can gain valuable insights into user preferences, behaviors, and pain points. Testing the product in realistic scenarios helps identify usability issues, bottlenecks, and limitations, ensuring the design meets expectations and delivers the desired user experience.

Read more about our Product Design and Development Services.

Functional Testing

Functional testing focuses on verifying that the physical prototype performs its intended functions accurately and consistently. By rigorously testing the functionality of the product, designers can identify and address any defects or limitations that may impact the user experience. Functional testing ensures that the product meets expectations regarding a reliable and intuitive experience for users.

Reliability Testing

Reliability testing assesses the durability, performance, and robustness of the prototype under various conditions. By subjecting the prototype to real-world stressors and scenarios, designers can identify potential weaknesses and areas for improvement.

This testing aims to enhance the reliability, robustness, and overall quality of the product, ensuring it can withstand the demands of everyday use and deliver a dependable user experience.

By embracing the concept of “fail early, fail often,” you create a culture of continuous improvement. Testing becomes an integral part of your development process, enabling you to create a product that truly resonates with your target users. So, don’t shy away from testing the prototype. Embrace it as a valuable opportunity to learn, iterate, and ultimately deliver a product that delights your customers.

Leveraging Outsourcing Companies for Effective Prototyping

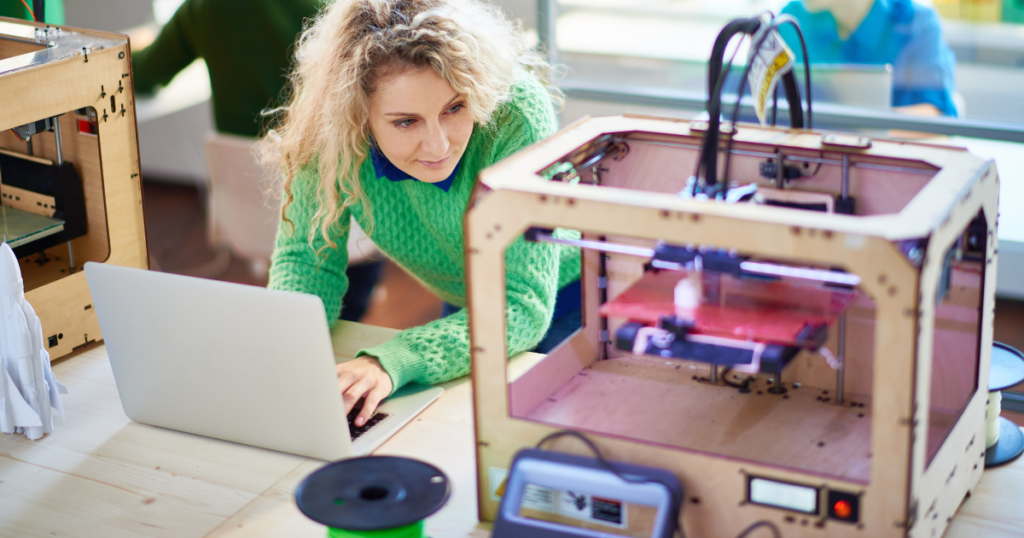

When it comes to developing a prototype, the DIY approach can have its drawbacks. Limited resources, lack of specialized knowledge, and time constraints can hinder the efficiency and quality of your prototypes. This is where working with companies specializing in product development can make a significant difference.

Product development companies bring a host of benefits to the table. Primarily, they possess the expertise and experience required for efficient and effective prototype development. With their specialized knowledge and access to advanced tools and technologies, outsourcing prototyping companies can bring your ideas to life in a professional and timely manner.

By leveraging their skills, you can tap into their wealth of experience and ensure a higher level of accuracy in your prototypes while building investor confidence in your ability to execute your plans or comprehend the intricate details.

However, it’s important to identify reputable outsourcing companies that align with your development needs. When evaluating potential partners, consider their expertise, experience, and track record. Look for companies that have successfully completed similar projects and have a portfolio that showcases their capabilities. Client testimonials and reviews can also provide valuable insights into their professionalism and reliability.

Read our blog post about how to Unlock Your Product’s Potential by Outsourcing Design & Engineering.

Additionally, consider factors such as communication and collaboration capabilities, cost-effectiveness, and the outsourcing company’s ability to meet deadlines. A strong working relationship and effective communication channels are essential for a successful partnership.

Conclusion

Developing a robust prototype is important in securing investors and achieving manufacturing success for startups. By adopting a goal-oriented prototyping mindset, you can impress potential investors and establish a solid foundation for your manufacturing endeavors. Engaging with product development companies that offer expertise and cost-effective solutions can develop a professional prototype, while testing ensures the product meets the requirements.

By leveraging the power of developing a prototype effectively, you can proudly demonstrate a product to potential investors and bring your innovative ideas to life. If you have any questions or need guidance with developing your prototypes, don’t hesitate to reach out to us at Zebulon Solutions.