Hardware Marathon: Installment 4

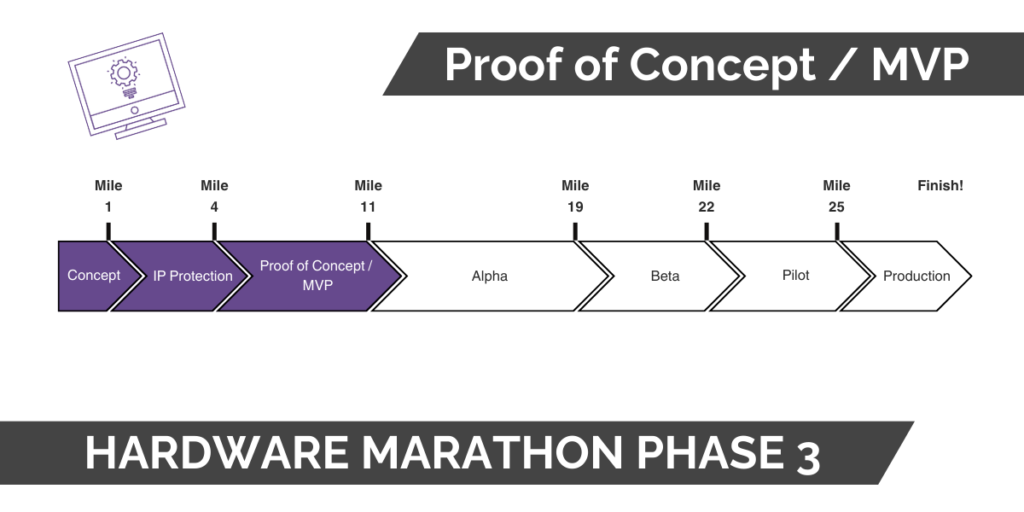

This post is the fourth in the series, “The Hardware Marathon.” In this series, I discuss the process involved in developing a hardware product from concept to production.

As the marathon continues, the tense anticipation at the beginning of the race has given way to loosened muscles and starting to fall into a rhythm. The fourth mile marker passes by and it feels good to run. Up ahead, is the first hill, but our runner pushes forward with confidence knowing what it will take to make it to the top and the hopeful expectation of a glimpse of the finish at the pinnacle.

In the hardware marathon, you have a plan to protect your intellectual property and you’re excited about designing your product. While the details of how to move into production aren’t clearly defined, you continue to move forward because the hill of developing a proof of concept has your attention now.

Proving out the Concept

Developing a product that meets the requirements for the target market consists of 3 interlocked steps:

- Proof of concept (PoC)

- Minimum viable project (MVP)

- Robust prototype

The PoC is focused on testing and proving specific features and/or the technology behind the product. Frequently, the PoC is focused on the core competency of the business and the intellectual property to be protected. The details about what the final product looks like may not be as critical as ensuring the underlying technology works as theorized.

Depending on the complexity of the product or system you built at the Concept phase, it may make sense to break the product down into subcomponents or subsystems. For example, if the product has electronics that are enclosed in a housing, it is advisable to develop the electronics and enclosure separately, but not in isolation since they will need to marry back up before this phase is completed. Early in this phase, it is appropriate to take shortcuts by using development kits to get firmware written for a basic functioning unit. If an app is required, preliminary work can be started on that. The electronics can be built using quick-turn manufacturers with larger components that are easy to swap out manually or use jumpers as the circuit is adjusted for functionality.

“A Proof of Concept is a quick way to get to an end result before you spend all the money to bring it together. Think of it as something a person would put together in the garage. It’s not going to look pretty, but it functionally proves out what you’re trying to do,” said Joe Steinman, Lead Mechanical Engineer at Zebulon Solutions.

For the mechanical enclosure, time can be saved later in the process by designing each of the components instead of a single printed enclosure. Each part can be fabricated using prototyping methods like additive manufacturing (3D printing) and evaluated for appearance, fit, and function before incorporating the electronics.

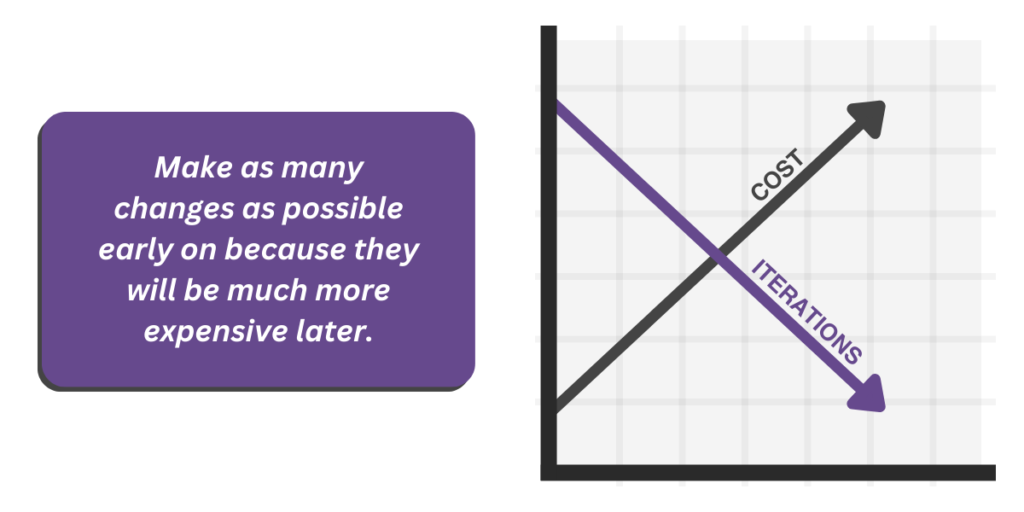

The most important goal at this stage is proving out the theory to ensure the assumptions you’ve made are true. As you work through this phase you may find additional features or technology that need to be added to your patent or changes where your assumptions were incorrect.

“Does the Proof of Concept do what you intended them to do? Does it meet your functional requirements and if not, is there a path to get there? It’s going to be an 85% solution. It’s not going to get you all the way there, but it will get you far enough that you can prove that you can get there,” said Steinman.

Leverage the Power of the People: The MVP

While the proof of concept (PoC) tests out the feasibility of the product and confirms the theory behind the design, the MVP enables maximum learning from the market to feed into your product with minimal effort. A business cannot be built on interesting technology that doesn’t have a market application. Getting feedback from prospective customers is invaluable in designing a product that people want.

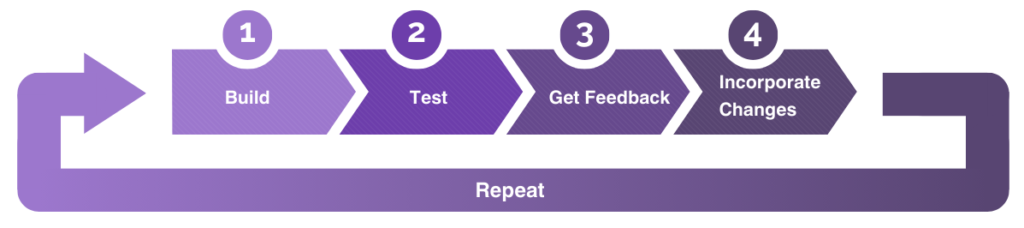

Neither the PoC or the MVP are a single iteration of “one and done.” During this stage, many different iterative designs could be created through the process.

This process could take a few weeks, months, or even years, depending on the complexity of the product, the skill of the team, and the resources available. Prematurely declaring a final version will add development time and costs in future phases because the product itself will declare when it is finished regardless of where you believe you are in the process.

The Robust Prototype: Frozen Requirements

You finally have a prototype that answers the many questions you had before you started this phase. The many iterations of testing the theory to see if the function can be achieved and incorporating market feedback on user experience have helped you define what is in scope and what is out of scope for this version of the product. Reducing product cost or incorporating more features will be pushed to a future version.

The idea of a “robust prototype”, however, is an oxymoron. Inherently a prototype isn’t robust. As it exists, it doesn’t actually meet the design requirements for durability, but it does provide a basis for clarifying the requirements. If you are forward thinking, you’ve considered how it will be manufactured and incorporated those requirements as well.

Perhaps the key indicator for when you are ready to exit this phase is when the requirements are at least 90% solidified. Ideally, they are written down and identified as what the product must do, some of the features you want to include, and those which are nice-to-have. Upcoming iterations will not significantly adjust the requirements, but the product will be modified to ensure the requirements are fully met.

Our runner has reached the top of the first hill and passed the 10th mile marker, it has been a challenge and the legs feel like jelly. While there is a sense of achievement in cresting the first hill, there are also hints of discouragement as a series of rising hills and valleys lie ahead with the finish line hidden from view. It is time for our runner to dig deep and push forward. Caution begins to enter the mind while feeling fatigue in the body.

Up to this point, there has been some work, but product development has been a lot of fun. At Zebulon Solutions, we consider the end of this phase to also have about 80% of the fun behind us and transitioning into 80% of the work in the project. It’s important to manage expectations that the product is far from ready to manufacture at this point. With most of the work ahead to bring this product to market, you will need the budget to get there.

The next blog in this series will look at the next major iteration: Alpha. The robust prototype will be the starting point with a focus on manufacturing readiness. In the meantime, click below to watch the latest webinar.