At Zebulon Solutions, we understand the thrill of invention. You have a brilliant concept, a product that will revolutionize the market, and you’re chomping at the bit to get it into production. That initial burst of creativity and developing prototypes into a Minimum Viable Product (MVP), is undeniably the “fun” part of product development.

However, there’s a crucial misconception we frequently encounter: prospective clients believing the MVP is the final hurdle before handing it to a supplier for production. In reality, the MVP is a critical step on a longer journey with two important, but often hidden, phases: Alpha and Beta.

These phases might not be as glamorous as brainstorming or creating a sleek prototype, but they’re essential for a product’s success.

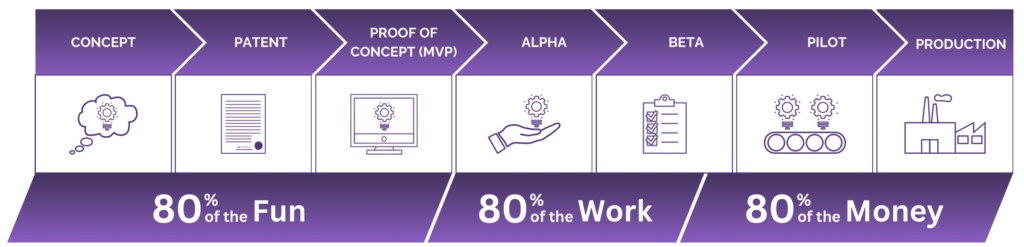

The 80/80/80 Rule of Product Development

At Zebulon Solutions we subscribe to the 80/80/80 rule of product development.

- 80% of the Fun: Concept, ideation, patenting, and the MVP phases are undeniably exciting. This is where creativity flows freely, and the potential of your product comes to life.

- 80% of the Work: The Alpha and Beta stages are where the rubber meets the road. Here’s where the real engineering happens, iterating the design and testing to ensure it functions flawlessly. This is meticulous, detail-oriented work that lays the foundation for a successful product ramp into production.

- 80% of the Money: Pilot production and full-scale manufacturing require significant investment. However, without the groundwork done in Alpha and Beta, these stages become exponentially more expensive due to unforeseen issues.

Why Skipping Alpha and Beta is a Recipe for Disaster

Imagine this: you’ve created a fantastic MVP, and you’re eager to get into production. You approach manufacturers, but your design lacks the refinement needed for mass production. Even if you’re fortunate enough to find a company who can build it, you’re setting yourself up for risks at every turn.

- High Manufacturing Costs: Manufacturers are hesitant to take on unrefined products. If they do agree, they’ll likely charge a premium to account for the extra work needed to get your product ready for production.

- Quality Issues: Rushing into production with an untested design can lead to manufacturing problems including:

- Low Yield: A high percentage of your products might be unusable due to design flaws. This means wasted materials, wasted manufacturing time, and a higher cost per usable product.

- Hidden Weaknesses: Products that haven’t been thoroughly tested might have weaknesses that only emerge during or after production. This can lead to recalls, replacements, and damage to your brand’s reputation.

- Rework and Redesign: Unforeseen issues during production might necessitate redesigning components or the entire product. This adds significant time and cost to the process.

- Missed Reliability Feedback: The Alpha and Beta phases provide invaluable testing opportunities to verify the requirements are met. By skipping these phases, you miss the chance to identify and address design shortcomings. This can lead to making changes after launch, which can be expensive and disruptive.

- Safety and Regulatory Concerns: Untested products could pose safety risks to users. This is a worst-case scenario that can result in lawsuits, product recalls, and severely damage your brand’s reputation. Even in a best-case scenario, skipping regulatory testing (e.g. FDA, FCC, FAA) could result in fines and industry-mandated stop-ships that both impact the bottom line with risk to your brand’s reputation.

Skipping the Alpha and Beta phases might seem like a way to streamline the development process, but it will cost more and take longer to achieve the desired results.

Alpha and Beta: Preparing for Reality

The Alpha and Beta phases are all about iterating on your MVP until it meets the requirements It’s in these phases that your product transforms from a promising concept into a manufacturable reality. Below is a breakdown of what happens in each phase.

Alpha Phase: First Draft of the Final Product

The Alpha phase is the iterative process of designing and executing the product against the requirements and for the production manufacturing processes. Up to this point, there has been design activity, but it has mostly been exploratory to determine what your product needs to do.

Once the design is completed, the parts are fabricated to be evaluated individually and then as a system. Here at Zebulon Solutions, our engineering team subjects your product to a battery of tests designed to confirm if the product meets the requirements. This is where the initial excitement of the MVP meets the nitty-gritty of real-world functionality.

Iterate, Iterate, Iterate

Within Alpha, there are almost always additional hidden iterations. Testing will inevitably reveal problems in the design. While it is good to plan for success, don’t be frustrated with failure that begins another round of design and testing. Each iteration should move the product closer to the requirements and ultimately what the market wants. Prematurely advancing the design to the next phase will increase your costs and extend your timeline.

The iterative process applies to test plans and requirements as well. It is better to make these changes early to avoid redoing engineering and design efforts later. A word of caution: trade-offs need to be carefully evaluated when changing requirements because designing a product the market won’t be interested in will lead to business failure.

Beyond Testing:

The Alpha phase isn’t just about identifying problems; it’s also about exploring solutions. While many problems are solved by adapting the design, considering how it is manufactured or tested could identify solutions. At Zebulon Solutions, our team works collaboratively with our clients to brainstorm creative solutions and understand the full picture.

By the end of the Alpha phase, you’ll have a much clearer picture of your product’s strengths and weaknesses. With a well-defined and tested design, you’ll be better positioned to enter the Beta phase with confidence.

Beta Phase: Preparing for Production

The Beta phase is where your product graduates from the highly iterative process in Alpha. If your approach has been comprehensive in Alpha, Beta should be a ‘tweak’ on the Alpha design before you start spending “80% of the money” on tooling and other capital expenditures to prepare for production.

The test results captured during the Beta phase are pure gold. It allows you to refine your product and address any concerns before full-scale production. This might involve making tweaks to the user interface, optimizing performance, or even making minor design changes based on user feedback.

We strive to solve most hidden iterations within Alpha, but you can still iterate here too. It is much worse to release a product to the market with fatal flaws, so carefully evaluate the flaw against the cost of a Beta redesign and the implications on repeating tests.

Commence 80% of the Money

When the engineers are confident that the design meets the requirements, custom tooling should be purchased and initial parts produced for evaluation against the design. Hopefully, only minor changes are needed as significant changes can be very costly.

While we’ve discussed testing within engineering up to this point, specific planning for how the product will be tested during production should be conducted. No one wants to consider defects being created in production, but it is a reality. It is better to find them in the factory than for your customer to receive a non-functioning or poorly functioning product. Frequently, production test systems can be a project of their own with requirements and iterations, so it is advisable to develop a test system in conjunction with the product.

Verification Testing:

The test plan developed and executed by engineers in Alpha will now be scaled up to more statistical quantities, utilizing certified laboratories as required. Laboratories may have been necessary in Alpha due to specialized equipment or testing protocols. A formal verification that the product meets regulatory and safety requirements will be necessary in Beta. Tests performed by these laboratories can be many thousands of dollars, so you will want high confidence the product will pass before starting the tests.

The Outcome:

By the end of the Beta stage, you’ll have a product that has been refined and tested by engineers and friendly end real users. You’ll have a wealth of feedback to inform the final design, ensuring your product is ready to launch with confidence and achieve market success.

The Zebulon Solutions Advantage

At Zebulon Solutions, we understand the importance of hidden iterations. Our experienced team will guide you through the Alpha and Beta phases, ensuring your product is refined and manufacturable. We’re here to help you with the “work” phases so you can reap the rewards in the pilot and production phases.

Don’t let the excitement of the MVP and success of production blind you to the iterative process between the two. Contact us today, and let’s turn your brilliant concept into a market-dominating reality.