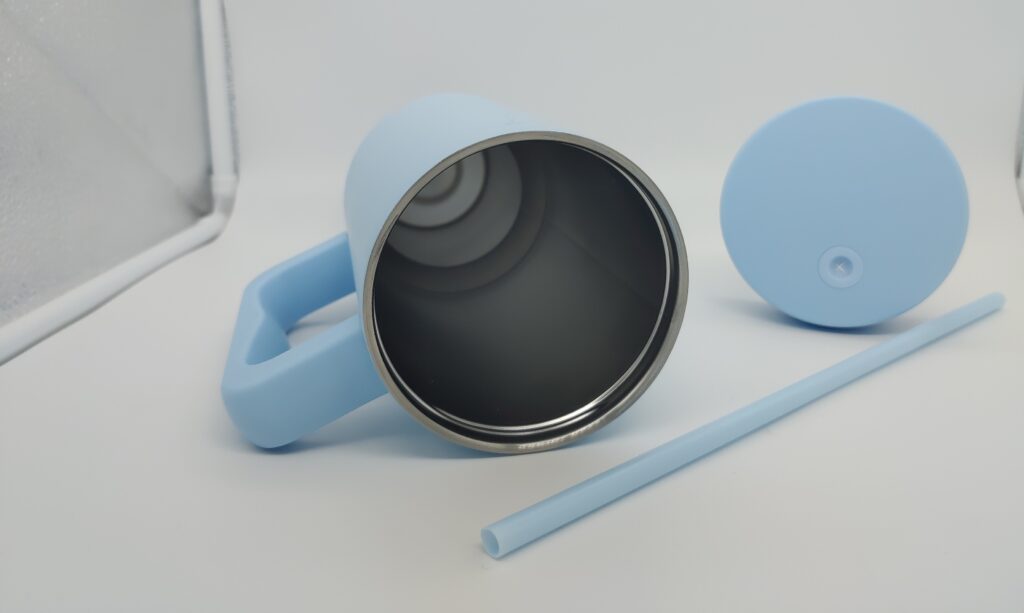

An independent design assessment provides an unbiased evaluation of a product’s design, functionality, and materials used. This brings a fresh perspective from someone not involved with the development of the product and therefore can increase the potential to discover flaws. For this review, Zebulon Solutions purchased the drink cup from a popular website.

User Observations

- Can only take one or two sips from straw until a vacuum is formed and user can no longer drink from straw

- Lid is hard to unscrew

functional requirements

- Cup is intended to be a spillproof

- Cup should keep the drink cold or warm as needed

- Should be able to drink from cup using the provided straw

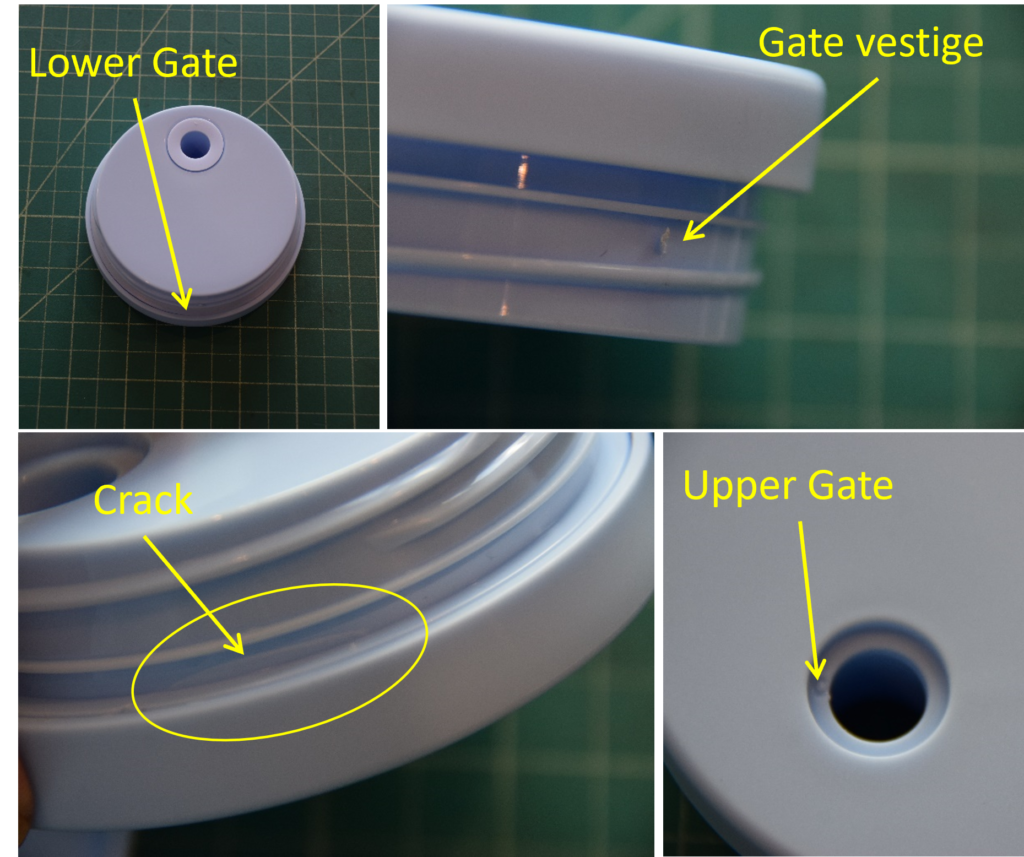

lid

OBSERVATIONS: The lid was untwisted from the drink cup. As you can see, the lid is comprised of two inseparable parts that appear to be welded together. The lower part has a gate opposite the straw hole. This led to knit lines adjacent to the hole which caused defects and cracks in the lid on the evaluated sample. Note that there is a very large gate vestige between threads. The upper part is gated with a hot runner at one side of the straw hole. And lastly, there is a very faint knit line opposite the gate.

RECOMMENDATIONS: Confirm production monitoring of these features

While these issues have been identified, they do not seem to be the source of functionality issues. Given the location of the knit lines, it is possible a crack could form in this location and reduce the useful life of the cup. Our recommendation would be to ensure these features are monitored during manufacturing to avoid degradation.

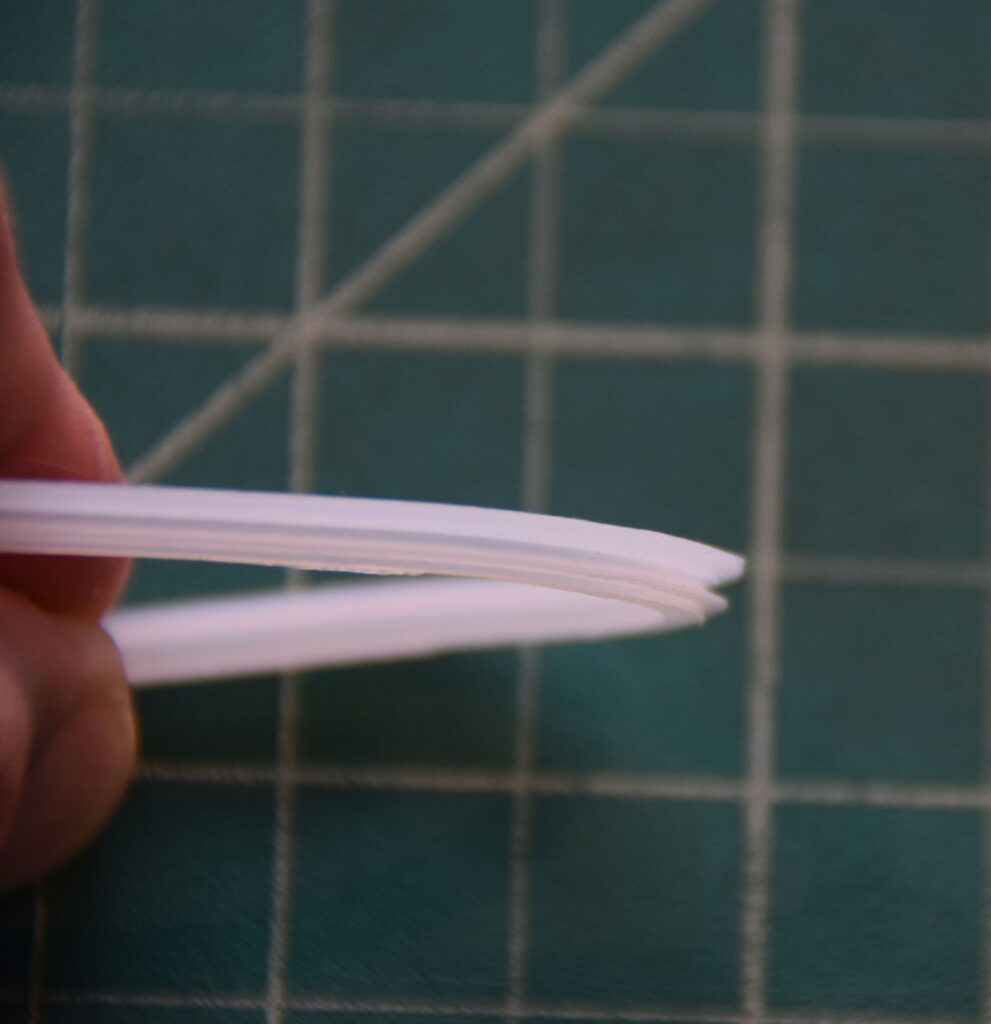

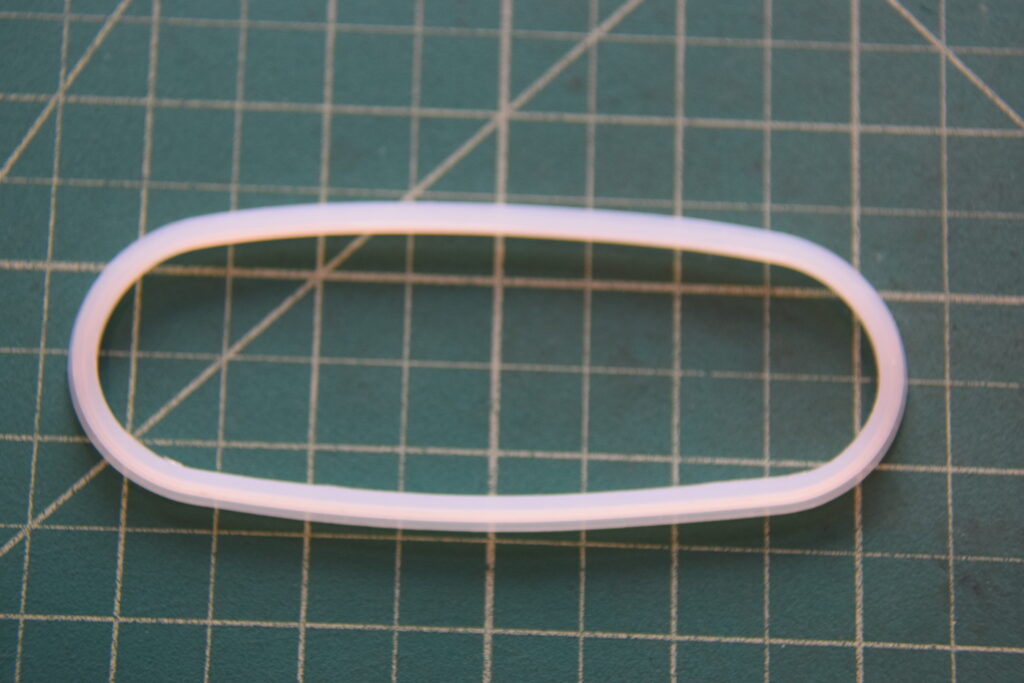

Outer Seal

OBSERVATIONS: The outer seal displayed below has a complex cross section for sealing beverage within the bottle. Based on appearance and texture, the seal is probably made of a clear TPE or silicone. Worth noting is that the seal is molded as an oval instead of circular. It is possible that the seal is not a custom component for the cup, but a purchased item that has been incorporated into the design.

RECOMMENDATIONS: None

While the shape was observed, given the flexibility of the seal, it is easily formed to fit with the round shape of the lid.

straw seal

OBSERVATIONS: The seal is made from TPE or silicone and is aggressively shaped and fits tightly in lid and against the straw. No burp vent was detected which would allow air in when suction is applied. This creates difficulties when trying to drink as vacuum pressure is created via suction with no relief valve.

RECOMMENDATIONS: Redesign seal or lid

A redesign to allow air to enter or add a pressure relief valve onto the lid. This could be as simple as a hole in the lid covered by a flap in the straw seal.

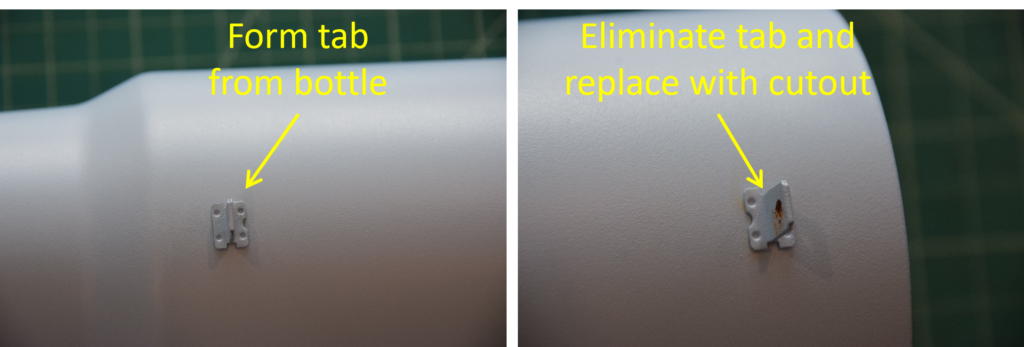

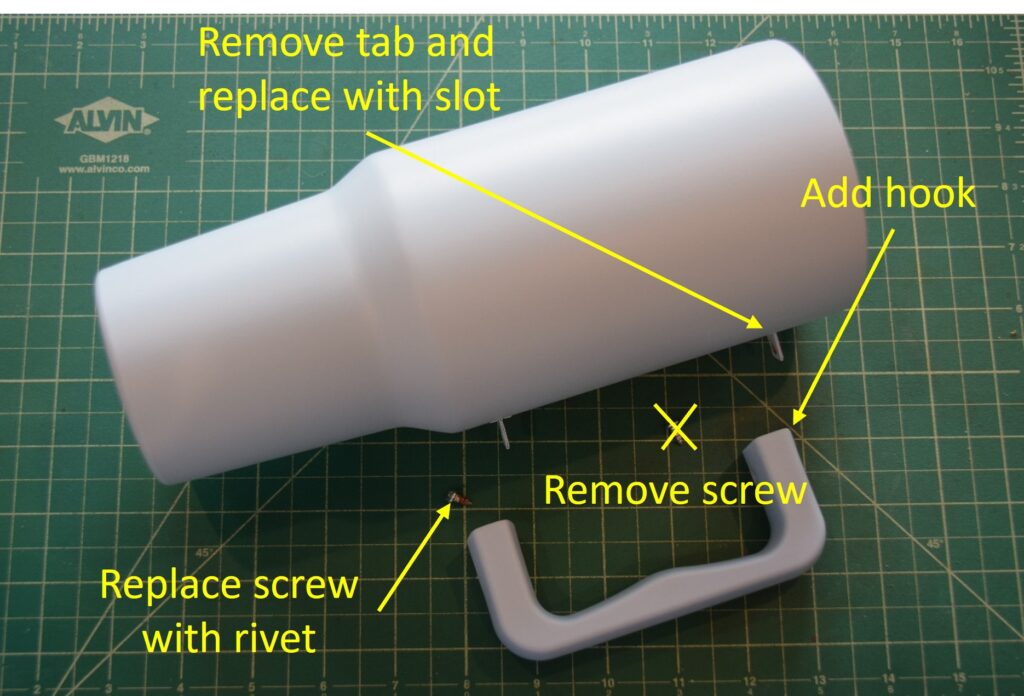

main bottle

OBSERVATIONS: The main bottle is created from 304 stainless steel which includes the inner, outer, tabs, and outer base plug. Note that the inner bottle is rolled, formed and laser welded. For the outer bottle and base plug, unsure of design due to paint on the exterior surface. There is 2x spot-welded tabs to secure the handle. And lastly, unsure about insulation used between inner and outer layers.

RECOMMENDATIONS: Possible redesign to reduce assembly time/ cost

If insulated with other than air or sealed gas, can tabs be formed out of outer shell and eliminate the two spot welded tabs?

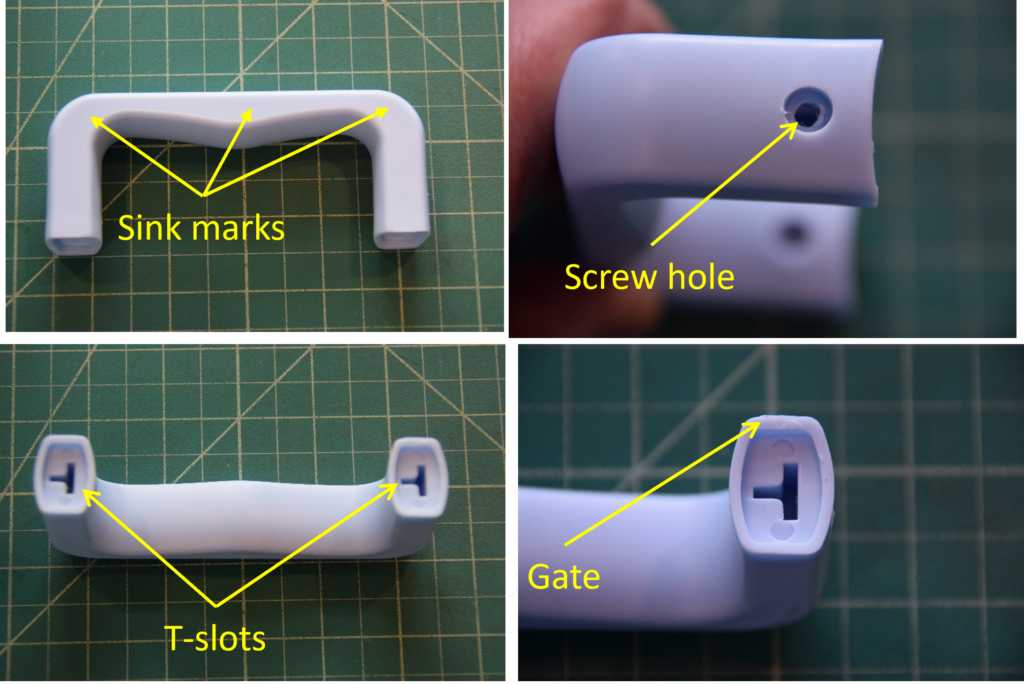

handle

OBSERVATIONS: The handle is held in place with two screws. The handle itself is a single part, with sink marks due to its thickness. Tool is a single pull with two slides or lifters for the screw holes. Note, T-slots are formed in the end to mate with tabs on the bottle and those slots also double as a place for the screws to protrude into.

RECOMMENDATIONS: Redesign to improve appearance and assembly ease

There is an opportunity to create a hook at the top end to eliminate a screw leaving the more accessible screw at the bottom. The second screw could also be replaced with a pop rivet. And for the handle itself, ribs could be added to the inside for reduction in material volume and elimination of sink marks or convert to foam molded part.

screws

OBSERVATIONS: The screws are self-tapping. However, upon removing the screws, it was noted that one exhibits signs of corrosion. For a newly purchased item, this is unexpected and unacceptable.

RECOMMENDATIONS: Update requirements

Check plating callout and/or change to stainless steel to eliminate corrosion.

straw

OBSERVATIONS: The straw is a simple thin wall extrusion that is cut to length.

RECOMMENDATIONS: None

Conclusion

Function: A valve is needed to allow the user to drink using the straw without creating an internal vacuum. This valve could be added by modifying the existing parts and not adding any additional parts.

Cost: The largest cost reduction opportunity would be the handle design and attachment. This could be accomplished by reducing the volume of plastic in the handle and adding a hook to eliminate one of the screws. This would reduce parts cost and assembly time.